Science

The significant event for all oxygen industry happened in 1959. Moscow VNIIKimash supplying project documentation to Balashikha engineering plant was entitled to build a filial in Balashikha.

The territory of the new building was adjacent to Balashikha oxygen plant, and – together with the plant newly named “Balashikha engineering plant named after the 40th October anniversary – made one whole city-forming complex. Understanding the importance of the developing cryogenic science for scientific and technological progress, the Council of Ministers of the USSR, in 1963, assigned funds enough for construction of new Institute buildings in Balashikha, on Lenin’s Avenue. At the time of building the production basis, the urban infrastructure was also appearing: apartment houses, a polyclinic, kindergarten, a school, and shops. The company’s possessing lodgings was helping it to hire personnel quickly. Experienced workers of VNIIKimash, having earlier had no normal housing conditions in Moscow, moved to Balashikha and formed the core of the new team, they became – due to the distribution system – tutors for many young specialists graduated from the best country universities.

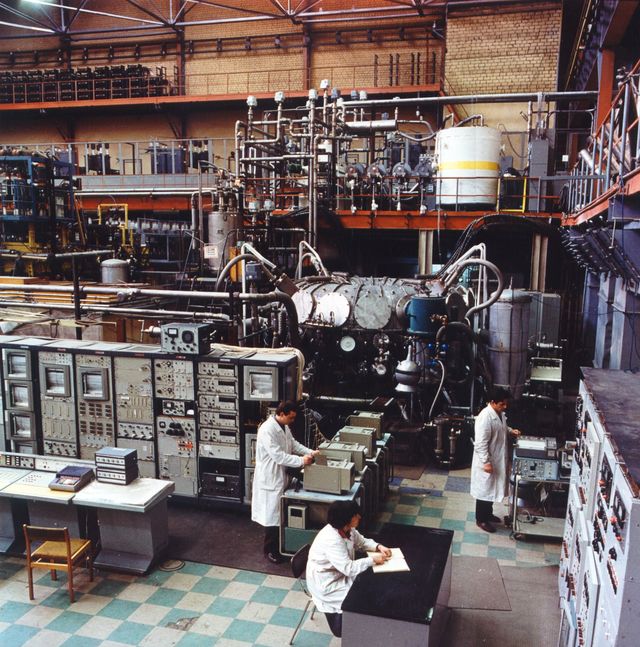

The first manager of the filial was a highly qualified professional, Candidate of Technical Science, V. V. Gustov. Duplicating the structure of VNIIKimash, the Institute nearly outright began working in operating mode. By the end of 1964, there functioned four engineering departments, ten laboratories, a machining workshop, Unit Г-2 produced 4.5 liters of liquid helium per hour. In the building of a separately built cryogenic station in 1965, a modernized liquefier ГС-2 produced 12 l/hr of liquid hydrogen containing 50% of modification vapour.

Gradually, the main scientific and design works was moving from the capital to the Moscow region. By order of the Council of Ministers of the USSR dated the 3rd of May, 1967, on the basis of VNIIKimash and engineering departments of Balashikha engineering plant named after the 40th October anniversary, the All-Union research and development institute of cryogenic engineering was founded, and Viktor P. Belyakov, Candidate of Technical Science, experienced rocket production specialist, was appointed to the position of its Director. Structural changes and moving the administrative services to Balashikha initiated by him have transformed the filial into the leading company, and the Moscow territory into the filial.

Viktor P. Belyakov, basing on the applied nature of the new Institute scientific researches, became the initiator of founding the R&D production facility (NPO) as part of Balashikha engineering plant named after the 40th October anniversary, VNIICryogenmash and former VNIIKimash. Officially, NPO “Cryogenmash” was established by the order of the Chemical and Oil Engineering Ministry dated 1972. The merging gave a powerful impetus to scientific researches. Comparatively young science became a wide field for innovators. Air separation plants of unprecedented capacity and unique projects for space-launching complexes set new tasks on heat exchange, hydrodynamics, adsorption and filtration, thermal insulation and evacuation, vibrations, safety, reliability, physical metallurgy and mechanical engineering for temperature conditions from +40 to -270 degrees Celsius or to absolute zero point, Kelvin temperature.

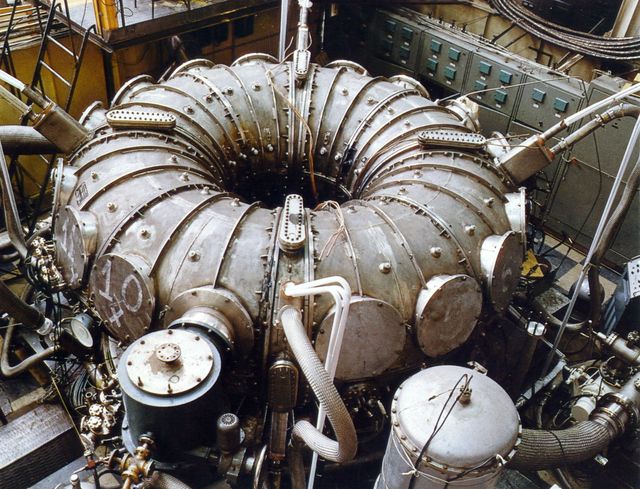

By 1980, JSC “Cryogenmash” was already on advanced positions like world-known manufacturers of cryogenic equipment. Large plants for separation air for oxygen, nitrogen and argon, hydrogen and helium liquefiers, hydrogen and oxidant fuel systems for space rockets, space simulators and medical pressure chambers, cooling systems for electric superconducting devices, tanks for cryogenic liquids and evaporators-gasifiers, brand new evacuation systems – these are far not a complete list of NPO “Cryogenmash” products.

To enlarge the scale of oxygen, nitrogen and argon production, large air separation units of Types КА-15, КтК-35, КА-32 and КАр-30 were designed, and their large-batch production was organized. In 1980-1982, the largest in the world by that time, air separation unit of capacity of 70 000 m3/h of oxygen was created. On the basis of these units, oxygen units of almost all metallurgic and chemical plants of the USSR, currently – of Russia and CIS countries, were manufactured, and more than 160 plants were exported to more than to 25 countries.

From the very origination of space-rocket hardware JSC “Cryogenmash” has been taking an active part in design and manufacturing of test bench and launching cryogenic-vacuum equipment for space infrastructure objects of Russia. JSC “Cryogenmash” has created large-scale liquid hydrogen, oxygen and nitrogen production units for supplying to bench and launching space-rocket complexes, including space-launching complexes “Baikonur” and “Plesetsk”; liquid cryoproducts storage and fuelling systems; in test space-rocket centers and space-launching complexes, among them are: unique cryogenic fuelling systems on deeply supercooled components in the frame of program for creating the space-rocket complex “ENERGIA-BURAN”; numerous space simulators and cryogenic pressure chambers, including the largest in Europe space simulator of 10000 m3 volume.

Cryogenmash is a pioneer in commercial-scale practical study of superconductivity. For the sake of cooling superconductive technical devices to the liquid helium temperature, there were more than 10 large-scale industrial helium complexes built containing a number of large-scale liquefiers, of capacity of 2400 l/hr and refrigerators of cooling power of 2500 Wt at the level of 4,5 K.

Equipment, patents and licenses of the company were in great demand among foreign companies. Having defended the theses, 20 candidates became Doctors of Technical Science, and 130 engineers became Candidates of Technical Science. A number of scientists, engineers and workers of JSC “Cryogenmash” received orders and medals, State and Governmental Prizes. The Chiefs of the company were titled “Heroes of socialist labour”, V. P. Belyakov – in 1983 and V. E. Kurtashin – in 1991.

Modern research & development and design institute of cryogenic engineering, being an organization department of JSC “Cryogenmash”, is a worthy successor of scientific traditions founded by P. L. Kapitsa.

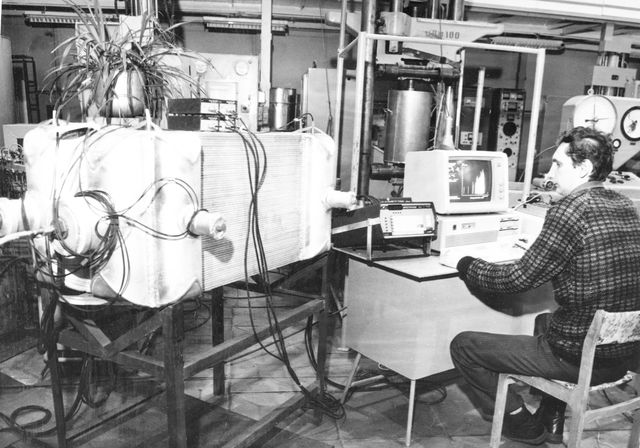

Unique specialists working at Institute create sophisticated high-technology equipment the performance parameters of which are not inferior, but often superior to those of foreign competitors’ products. In recent years, the company is active investing in development of the modern bench-test and laboratory base, in design of new products and mastering new technologies.